Besides grapes, wine can be made from various fruits. With a high yield of organic apples from our garden tree, some were used to make apple wine. The process is simple, cheap with six basic processes; harvesting, crushing, pressing, fermentation, clarification and maturation. The end result is definitely refreshing and rewarding. Best served chilled and enjoyed with the main meal. If sweetened, then sipped as a dessert drink.

To make wine, select apples that are ripe, firm and free of any decay. Rotten apples can give out moldy and off flavours. An immature or unripe fruit has high starch content and astringent compound with the starch creating issues in juice clarification. Overripe apples are not suitable for wine making.

Apple wine is low in calories and ideal for weight watchers. Has a low glycemic index and preferable for diabetics. Contains high amount of calcium and good for bones. Relieves diarrhea and sore throats. Strengthens the immune system. Prevents heart and cardiovascular disease. Improves blood flow to the brain thereby, promoting mental vitality. Has many health benefits and a great substitute to the grape variety.

Terms in winemaking:

To make wine, select apples that are ripe, firm and free of any decay. Rotten apples can give out moldy and off flavours. An immature or unripe fruit has high starch content and astringent compound with the starch creating issues in juice clarification. Overripe apples are not suitable for wine making.

Apple wine is low in calories and ideal for weight watchers. Has a low glycemic index and preferable for diabetics. Contains high amount of calcium and good for bones. Relieves diarrhea and sore throats. Strengthens the immune system. Prevents heart and cardiovascular disease. Improves blood flow to the brain thereby, promoting mental vitality. Has many health benefits and a great substitute to the grape variety.

Terms in winemaking:

- Sterilization - process of eliminating the growth of harmful bacteria. All equipment must be sterilized with metabisulphite. A 50 gram pack is easily dissolved in a gallon of tap water. After sterilizing the supplies with this solution, do not rinse them again with tap water. The metabisulphite solution is reusable for up to 6 months.

- Hydrometer - used to measure the amount of sugar in the juice or wine.

- Fermentation Lock - allows fermentation gases (C02) to escape, while preventing air (02) from entering the container. The airlock has to be filled with the sterilizing solution up to the indicated line.

- Fermentation - yeast converts the sugar in the juice to alcohol and carbon dioxide gas that is released through the fermentation lock.

- Racking - method of transferring the wine from the original carboy to a second one, leaving the sediments in the original one to be discarded. During racking, the second carboy must be placed lower than the first to prevent sediments from entering the siphoning hose.

Apples from our garden

Fermentation - Must still cloudy

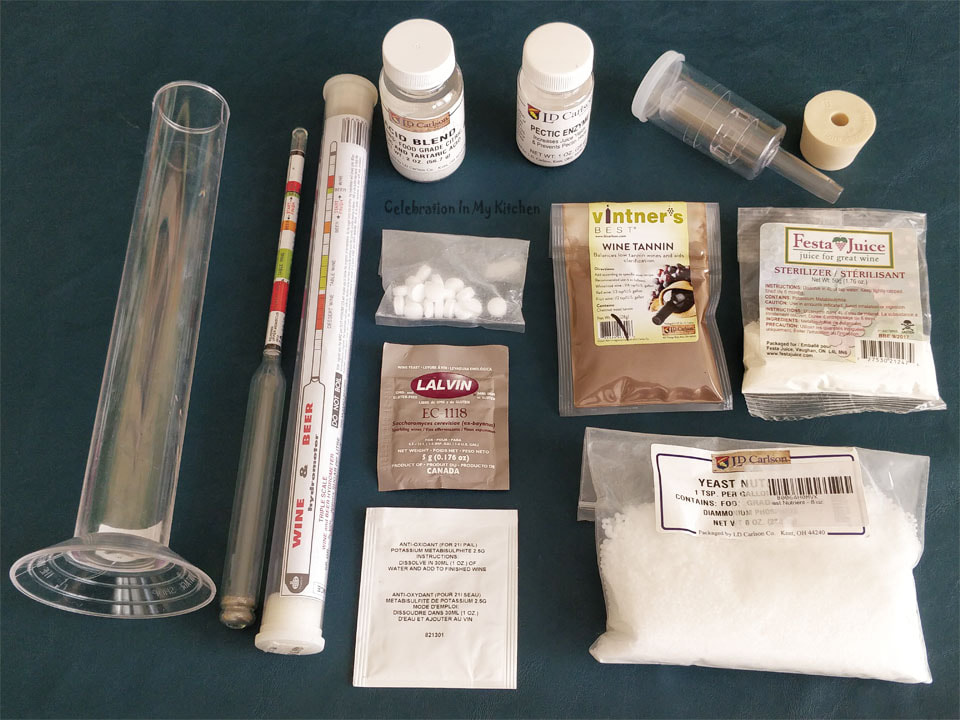

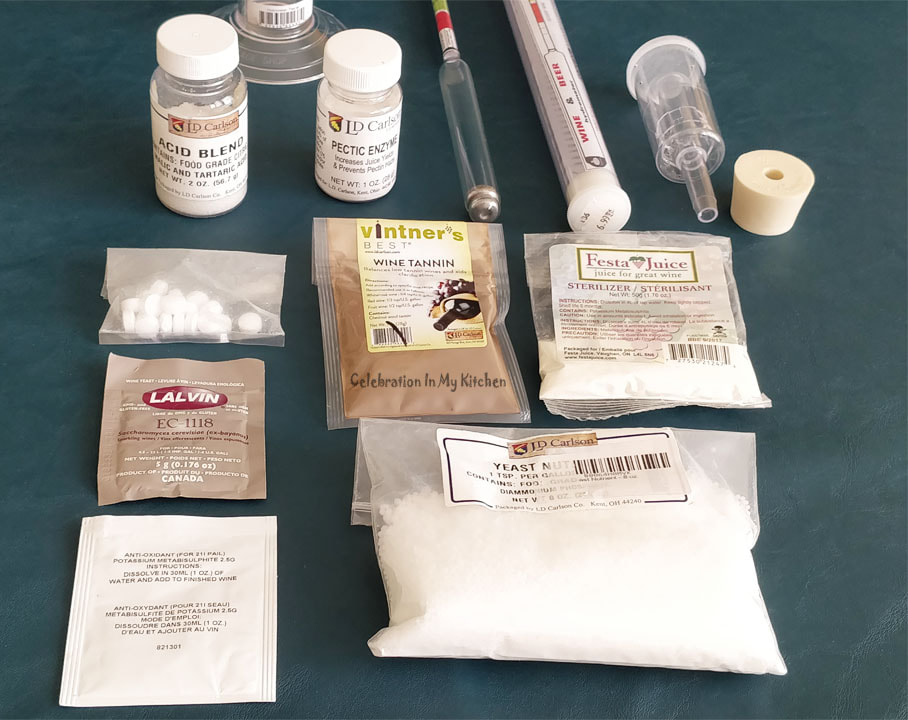

Left - hydrometer, Top - acid blend, pectic enzyme, fermentation lock and rubber stopper

Left - campden tablets, yeast and antioxidant

Right - wine tannin, sterilizer & yeast nutrient

Right - wine tannin, sterilizer & yeast nutrient

Bucket lid, bottle filler, stirrer, auto siphon with hose

Homemade Apple Wine

(Yields 1 gallon)

You will need:

1. Primary fermenter (large plastic food grade bucket with a lid able to support an airlock)

2. Hydrometer

3. Two glass carboys or demijohns of 1 gallon capacity

4. Siphoning hose

5. Two fermentation locks

6. Two rubber stoppers

7. Funnel

8. Sterilization powder

9. Thermometer

10. Nylon straining bag

11. Strainer

12. One empty wine bottle (for extra must)

13. Stirrer

14. Auto siphon

Ingredients:

15 lbs apples, about 60 (use a combination of tart and sweet)

2 1/4 cups sugar

1 campden tablet

1/2 teaspoon pectic enzyme

1/4 teaspoon tannin

1 1/2 teaspoons acid blend

1 package yeast (5 grams)

1 teaspoon yeast nutrient

1/2 teaspoon antioxidant (potassium metabisulphite, added before bottling)

Method:

Sanitize all equipment with the sterilizing solution, which is reusable for up to six months.

Wash the apples, remove the core, chop and press out the juice. Alternatively, puree apples and transfer in a nylon straining bag. Put the nylon bag and juice in the primary fermenter (bucket). We tied the bag to a stick and placed it horizontally over the bucket. Thus raising the bag up and allowing the juice to drip down. Press the juice out through the mesh and discard the pulp.

To the juice, add sugar, crushed campden tablet, pectic enzyme, acid blend and tannin. Stir well to dissolve solids and cover the bucket with a lid secured with an airlock. Ensure to have enough must, 4 litres plus extra to fill a wine bottle. The extra required to "top off" later in the process to help prevent oxidation. Distilled water can be added to make the required quantity of 4 litres, but we had more than enough juice.

After 24 hours when the must is 65 to 70 degrees F, add yeast and yeast nutrient. Put on the lid with an airlock.

Note:

Stir daily and in three to five days, the specific gravity on the hydrometer should reach 1.040 dropping from 1.090 as the yeast feeds on the sugar.

Then, siphon the must from the primary fermenter (bucket) into a glass carboy and wine bottle, while discarding the sediments. Leave about 10% space at the top for fermentation gases. Secure both containers with airlocks.

After 3 to 4 weeks, when fermentation is complete and specific gravity has reached 1.000, siphon the wine into a secondary sanitized carboy. Top up with the extra must from the wine bottle so there is minimal air space in the neck of the container to prevent oxidation. Reattach the airlock and get rid of the sediments from the first carboy. Simultaneously, transfer must from the wine bottle into a smaller bottle, leaving minimal air space (as above) and secure with an airlock.

After two months, siphon the wine off the sediments again or repeat process until wine is clear. In the video above, you will notice that the wine is still cloudy.

Once wine is clear, add the antioxidant to stabilize the wine before bottling.

To sweeten wine, include sugar as desired after wine is stabilized. We did not add any sugar at the end, wine is delicious on its own, tasted after a year.

Let wine age for 6 months to 1 year. The complexity of the flavour develops with age.

Note:

(Yields 1 gallon)

You will need:

1. Primary fermenter (large plastic food grade bucket with a lid able to support an airlock)

2. Hydrometer

3. Two glass carboys or demijohns of 1 gallon capacity

4. Siphoning hose

5. Two fermentation locks

6. Two rubber stoppers

7. Funnel

8. Sterilization powder

9. Thermometer

10. Nylon straining bag

11. Strainer

12. One empty wine bottle (for extra must)

13. Stirrer

14. Auto siphon

Ingredients:

15 lbs apples, about 60 (use a combination of tart and sweet)

2 1/4 cups sugar

1 campden tablet

1/2 teaspoon pectic enzyme

1/4 teaspoon tannin

1 1/2 teaspoons acid blend

1 package yeast (5 grams)

1 teaspoon yeast nutrient

1/2 teaspoon antioxidant (potassium metabisulphite, added before bottling)

Method:

Sanitize all equipment with the sterilizing solution, which is reusable for up to six months.

Wash the apples, remove the core, chop and press out the juice. Alternatively, puree apples and transfer in a nylon straining bag. Put the nylon bag and juice in the primary fermenter (bucket). We tied the bag to a stick and placed it horizontally over the bucket. Thus raising the bag up and allowing the juice to drip down. Press the juice out through the mesh and discard the pulp.

To the juice, add sugar, crushed campden tablet, pectic enzyme, acid blend and tannin. Stir well to dissolve solids and cover the bucket with a lid secured with an airlock. Ensure to have enough must, 4 litres plus extra to fill a wine bottle. The extra required to "top off" later in the process to help prevent oxidation. Distilled water can be added to make the required quantity of 4 litres, but we had more than enough juice.

After 24 hours when the must is 65 to 70 degrees F, add yeast and yeast nutrient. Put on the lid with an airlock.

Note:

- Must is the unfermented juice before it is converted to wine.

- Hydrometer is used to determine the natural sugar content of the must. It is important to take a hydrometer reading before and after adding sugar. Starting specific gravity should be 1.085 to 1.090, so add sugar accordingly. The natural sugar content varies depending on the type of apples used.

Stir daily and in three to five days, the specific gravity on the hydrometer should reach 1.040 dropping from 1.090 as the yeast feeds on the sugar.

Then, siphon the must from the primary fermenter (bucket) into a glass carboy and wine bottle, while discarding the sediments. Leave about 10% space at the top for fermentation gases. Secure both containers with airlocks.

After 3 to 4 weeks, when fermentation is complete and specific gravity has reached 1.000, siphon the wine into a secondary sanitized carboy. Top up with the extra must from the wine bottle so there is minimal air space in the neck of the container to prevent oxidation. Reattach the airlock and get rid of the sediments from the first carboy. Simultaneously, transfer must from the wine bottle into a smaller bottle, leaving minimal air space (as above) and secure with an airlock.

After two months, siphon the wine off the sediments again or repeat process until wine is clear. In the video above, you will notice that the wine is still cloudy.

Once wine is clear, add the antioxidant to stabilize the wine before bottling.

To sweeten wine, include sugar as desired after wine is stabilized. We did not add any sugar at the end, wine is delicious on its own, tasted after a year.

Let wine age for 6 months to 1 year. The complexity of the flavour develops with age.

Note:

- One gallon is equal to 16 cups (4 litres).

- Sugar is an essential component in the process of fermentation with yeast metabolizing sugar into ethanol (alcohol) and carbon dioxide.

- Campden tablets prevents the growth of mold, bacteria and wild yeast. Keeps the wine from turning into vinegar or getting spoil. Recommend dosage is 1 tablet per gallon before fermentation.

- Pectic enzyme are proteins used to clear the wine by breaking down pectin to prevent a "pectin haze". Also aids in the extraction of colour and juice from fresh fruits.

- Tannin is added to achieve the pleasing astringency with a balance of proper dryness and mouthfeel.

- Acid blend helps establish a vigorous fermentation, bringing liveliness and the fruity flavour.

- Yeast converts sugar into ethanol (alcohol) and carbon dioxide.

- Yeast nutrient assist the wine yeast in producing a complete and rapid fermentation.

- Antioxidant stabilizes the wine, preventing further yeast growth and acts as a preservative to prevent oxidation. Recommend dosage is 1/2 teaspoon per gallon.

- Supplies including sweetener (in case you want to sweeten the wine) and some ingredients are available at Festa Juice locations: http://www.festajuice.com/locations. The rest can be ordered from Amazon Canada.